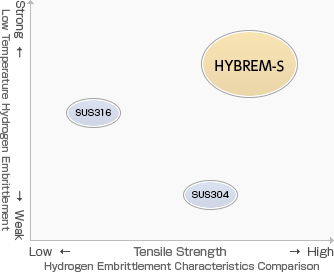

HYBREM®-S, is hydrogen embrittlement resistant stainless steel spring wire that has superior hydrogen embrittlement resistance and spring wire characteristics.

It is developed to be used under low temperature, high pressure hydrogen atmosphere conditions such as hydrogen stations or fuel cell vehicles-related.

- 1. Good Hydrogen Embrittlement Resistance

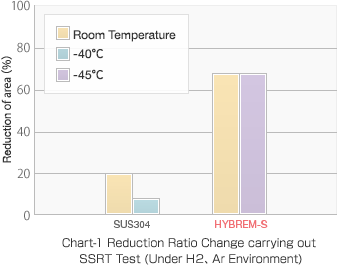

- Even under low temperature condition, its reduction ratio will not go down when carrying out ultra-low strain rate tensile test under high pressure hydrogen atmosphere.

- 2. High strength

- Tensile strength equivalent to SUS304(WPB)

- 3. Good Spring Characteristics

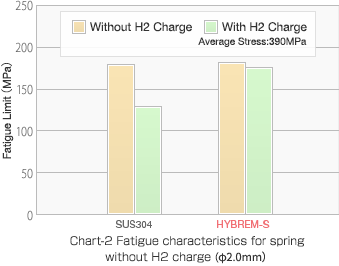

- Fatigue limit decline is kept to the minimum when carrying out fatigue test under hydrogen charged atmosphere.

- ・ High Pressure Hydrogen Gas Pressure Control Valve (Main Stop Valve、Pressure Reducing Valve、Check Valve)

- ・ High Pressure Hydrogen Filling Valve

- ・ Spring for Fuel Cell Vehicles

- ・ Springs for Stationary Fuel Cell Systems

| diameters (mm) | Tensile strength (N/mm2) |

|---|---|

| 0.50 - 1.00 | 1850 - 2100 |

| 1.20 - 1.40 | 1750 - 2000 |

| 1.60 - 2.00 | 1650 - 1900 |

| 2.30 - 2.60 | 1550 - 1800 |

| 2.90 - 4.00 | 1450 - 1700 |