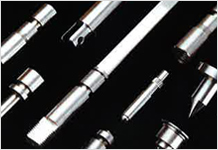

Nippon Seisen possesses a wide variety of steel types for shaft use, and we can suggest optimal steel types which maintain both hardness and machinability.

| Steel Types | Austenite type | SUS303、SUS303CU、NAS303N | |

|---|---|---|---|

| Ferrite type | SUS430F | ||

| Martensite type | SUS410、SUS410F2、SUS416、SUS420J1、SUS420J2、SUS420F、SUS420F2、SUS440C | ||

| Wire diameters | 0.8mm - 8.00mm | ||

| Treatment | S(W1) 1/8H, 1/4H(W2) | ||

| Finishes | NB (standard finish), EB (polished finish), UB (highly polished finish) | ||

| Standards | JIS G4309 | ||

| Steel Types | NAS316F | |

|---|---|---|

| Characteristics | NAS316F is a material which combines corrosion resistance equivalent to 316 with good machinability. |

| Steel Types | DSH400F | |

|---|---|---|

| Characteristics | DSH400F offers the machinability of SUS303 together with strength and toughness comparable to 304. |

| Steel Types | DSR7B | |

|---|---|---|

| Characteristics | DSR7B is a material with corrosion resistance and workability approximating that of SUS420J2, and through conventional hardening it can exhibit the same hardness and abrasion resistance as 440C. |

| Steel Types | DS205, NASNM15K, NASNM15N |

|

|---|---|---|

| Characteristics | All of Nippon Seisen's high hardness nonmagnetic materials possess magnetic permeability much lower than that of SUS316 as well as superior abrasion resistance. |

| Steel Types | DSR6F | |

|---|---|---|

| Characteristics | DSR6F possesses corrosion resistance equivalent to SUS303 despite being a ferrite type, and is also ideal for high precision machining with its superior workability resulting from machinability 8 times that of SUS303. |